If you have decided to start your brand new singer’s sewing machine. Then make sure you know set up a Singer sewing machine. Because before working on a project, this initial step is very important.

However, this topic is wide enough to cover several important topics and features about a singer sewing machine. We will be trying to cover the essentials of setting up a singer’s sewing machine right in this post.

When you receive your new singer Sewing Machine, you get a manual of your machine along with it. That manual covers almost everything that you need to know for setting up your sewing machine and running it eventually.

But not everyone got time for that long detailed booklet. Let me share the foundational essentials here that will be ample for you to begin your sewing journey.

Know your Machine!How to Set up a Singer Sewing Machine

Once you have opened your sewing machine, it’s better to acknowledge its model, basic parts, and how to use it. But the most important of all are precautionary measures.

Any electrical appliance should be treated carefully as it can cause harm like; burn electric shock, injury, and even fire.

That’s why an electrical Singer Sewing machine should not be left unattended. If you need a break in between your ongoing project, make sure to unplug the sewing machine for that pause.

Switching off the machine while lubricating, cleaning, or making any changes near the needle area is compulsory as well. Because; “Prevention is better than cure”.

Singer also suggests keenly reading the manual before starting to work on a sewing machine and keeping that near your machine. And in case of handing the sewing machine to a third party, send the manual alongside.

The essential setup plan of basics that a sewer should be familiar with are four umbrella points.

- Machine Basics

- Threading the sewing machine

- Sewing features

- Maintenance & General information

1. Machine Basics

Your Singer sewing machine will come along with its principal parts and accessories. You should be able to connect the principal parts and use them accordingly.

For instance, connecting the machine with an accurate power source. The polarized electric cord should match the polarized socket to abstain from fire or shock.

The foot control pedal is responsible for regulating the speed of sewing. So the two are connected to a single cord that needs to be inserted in a safe right electric socket to start your sewing machine.

Secondly, the accessories include almost all the important items that one needs for a start. For instance, a standard singer sewing machine comes with the all-purpose foot, zipper foot, buttonhole foot, 3 bobbins, 3 needle packs, darning plate, L-screwdriver, seam ripper brush, and 2 spool pin felts.

Isn’t it amazing?

2. Threading the Singer sewing machine

The most important step is Threading. You always need to thread your sewing machine before beginning any new project.

Threading depends on the fabric material that you are going to use. For this, you’ll have to thread the bobbin and insert it properly according to instructions, and secondly the upper spool pin and insert at its place accurately.

You can find complete step-by-step procedures for winding the bobbin inserting that in its place and threading the upper thread.

Then, after threading is done, you need to choose from the patterns in which you want to stitch.

3. Sewing Features

How to choose a pattern?

Choosing a pattern is so easy that you just need to turn the pattern choosing dial in either direction. And set the dial to any of your desired patterns, like straight stitch. You can do reverse sewing as well or even remove the work too.

The thread cutter in front of the presser foot sharply cuts the excessive thread so you won’t need to go and grab a scissor amongst your project.

The sewing machine can also work on buttons and create buttonholes too with its double-level lifting presser foot. It can also work on layers of fabric.

The darning plate, extension table, and presser foot shank are also insertable in a simple singer sewing machine.

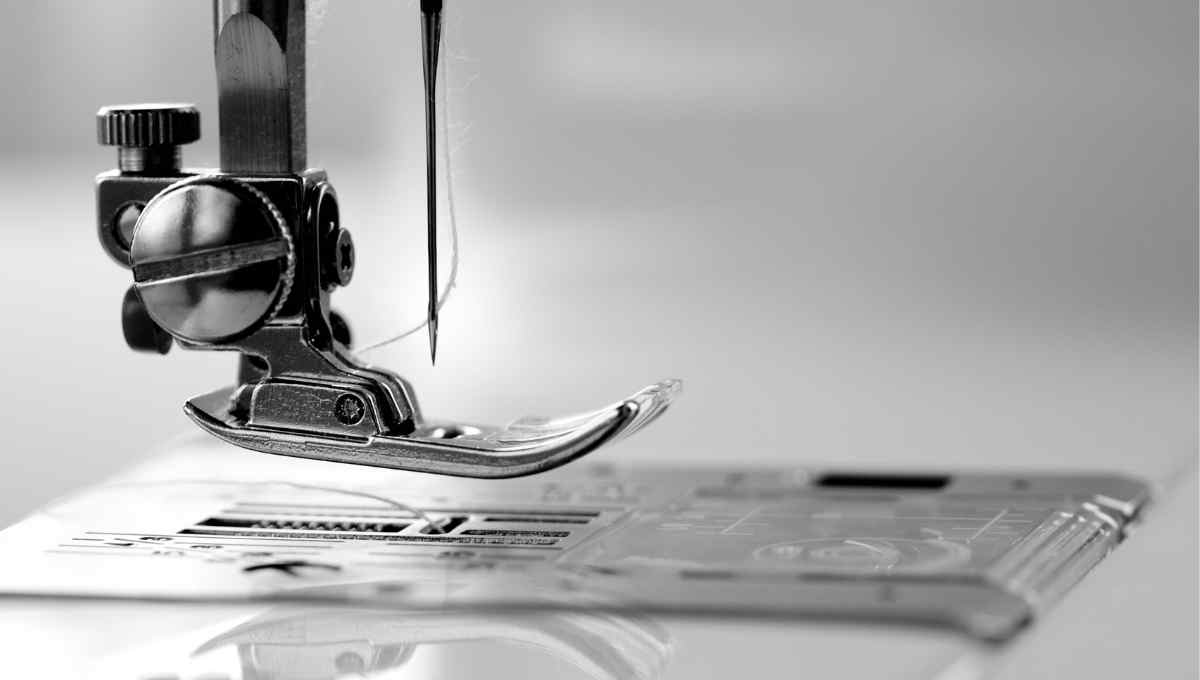

How to insert needles?

Besides threading and pattern selection another important setup initial is how to insert a needle in a Singer sewing machine. This is a detailed procedure that I discussed in a previous post. I am sharing the tidbits here too.

Needles can be inserted automatically as well as manually. This means using an automatic needle inserter and threader or using your hand.

To do it manually, First loosen the screw near the needle clamp and just grab the right needle with its flat side facing the back of the sewing machine. Push that needle as far above as it can reach and just tighten the needle clamp by tightening the screw. There’s more to it considering the Precautions.

To do it with a Singer needle inserter, the job gets easier. As your hand doesn’t go near the needle in any case there are fewer chances of self-harm or needle breakage.

The Singer manual includes a chart for the needle, thread, and a fabric selection guide. It’s good to consult that as a beginner in the industry.

4. Maintenance & General Information

Plenty of questions arise concerning the maintenance and safety of a sewing machine. But the most common queries include issues about oiling or lubricating, cleaning, and how to do that.

Well, these two basic questions are the master head or originators of other questions. For instance, if you don’t clean or oil your sewing machine, this will make it jam which will further cause skipped stitches, needle breakage, and even damage to the entire machine mechanism.

Therefore, cleaning and lubricating are the necessary maintenance elements that keep your machine running smoothly.

Tips & Tricks to Troubleshoot

Issue 1: Upper thread keeps breaking?

Reason: The machine may not be threaded rightly, or the upper tension must be too tight, the thread may be thicker for the needle, or maybe the needle is bent.

Solution: Rethread the machine, use a larger needle, reduce the tension, or replace the needle.

Issue 2: Lower thread keeps breaking?

Reason: the lower thread tension might be too tight, the bobbin may not be inserted properly or the thread in the bobbin must be improper.

Solution: The bobbin case and thread in the bobbin should be placed accurately. The tension should be in balance.

Issue 3: Skipped or uneven stitches?

Reason: Wrong size needle, poor quality of thread, damaged needle, or maybe the fit is not attached properly.

Solution: A right-size needle should be replaced which will surely help.

Issue 4: Your machine is making noise?

Reason: the lint or excessive oil on the hook or the needle bar can cause noise. Or another cause can be needle damage.

Solution: Cleaning can help, try tidying the feed dogs and hook as per instructions. And replace the needle too.

Issue 5: Machine keeps jamming?

Reason: The thread might be stuck in the hook.

Solution: Remove the bobbin case and upper thread, then turn the handwheel in either direction and remove the thread.

That’s everything basic that you need to know before setting up a machine. Enjoy your new singer-stitching robot!